In today’s fast-moving electronics and semiconductor industries, manufacturers must balance speed, precision, and reliability to stay competitive. At the heart of this ecosystem are the Original Equipment Manufacturers (OEMs), the innovators behind the machines that power everything from chip production to electronics assembly.

To support its partners, Delta hosted OEM Day 2025 in Penang, Malaysia on 28 May, bringing together industry leaders, professionals, and partners to exchange ideas and strengthen networks within the smart manufacturing ecosystem.

Key Hardware Highlight: High-Precision Motion Control for Complex Applications

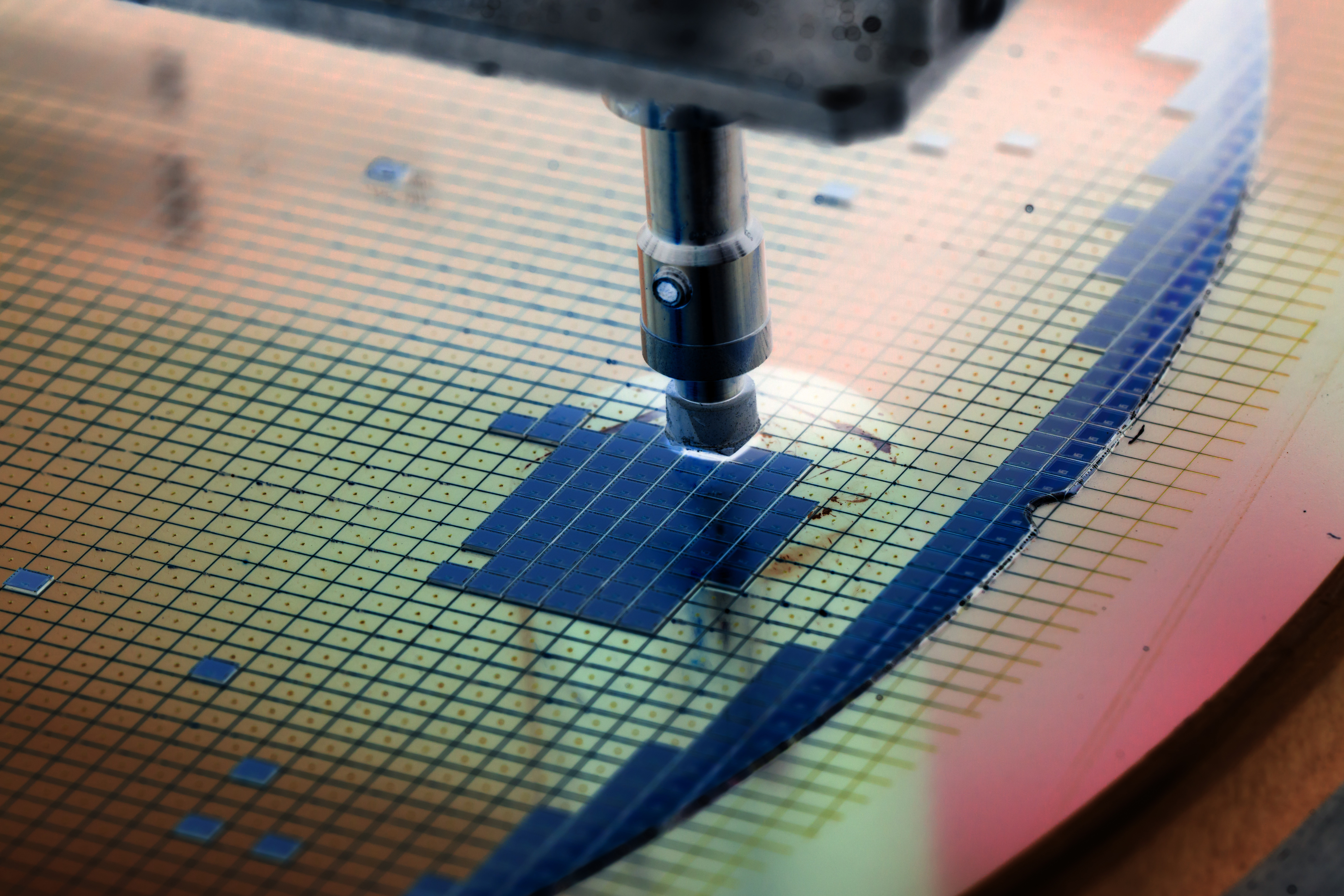

From die-cutting and sorting to chip shooters and optical inspection systems, visitors saw how Delta’s AX Series motion controllers and ASDA servo drives enable machines to move with remarkable accuracy and coordination. Acting like the brain of the system, motion controllers send precise instructions to drivers driving the motors, telling them how far to move, how fast, and in what order. This allows machines to carry out intricate, multi-step operations with perfect timing and consistency.

These systems are built to handle complex, multi-axis movements with high speed and stability. In one example shown, a semiconductor machine achieved greater precision in chip transfer using Delta’s AX-8 controller. Thanks to real-time motion control and high-speed communication, delicate wafers could be picked and placed smoothly, improving efficiency while reducing the risk of damage.

In addition to providing the powerful “brain” of machine systems, Delta showcased the “muscle” that drives precise and delicate motion as well. The Linear Pocket Actuator (LPL) is a compact, high-performance device that delivers exceptional speed and precision, with force control down to the gram level. Its unique blend of power and finesse has made it a favorite among semiconductor machine manufacturers.

Delta also demonstrated its PC-based motion control cards, which are compact modules installed in industrial computers that act as both the brain and eyes of the system. These cards not only control movement, but also capture images and trigger specific machine actions based on what they see. This is especially important in Automated Optical Inspection (AOI) machines, where quality checks must be fast, accurate, and automated.

Other featured solutions included Delta’s servo presses for precision force control, the smart screwdriving system for consistent fastening.

Industrial robots for handling, inspection, and assembly were also on display, offering greater flexibility and safety in high-mix, high-speed manufacturing environments.

Key Software Highlight: Smart Tools to Design, Simulate, and Optimise

Alongside its hardware, Delta introduced a powerful lineup of automation software that supports OEMs from concept to commissioning.

The DIATwin Virtual Machine Platform allows developers to simulate machine motion, layout, and performance before building physical prototypes, which reduces trial-and-error while speeding up product development.

Also featured were DIAEAP+ Line Manager, which helps monitor and manage full production lines in real time, and DIASSA Smart Screwdriving Analysis, which offers traceability, risk prediction, and insights for better fastening quality in automated assembly.

Delta also showcased its equipment communication software, DIASECS (designed for semiconductor applications) and DIACFX (for electronics assembly), which simplify data exchange and improve production efficiency by seamlessly linking machines and control systems.

These tools create a connected digital workflow, allowing machine builders to design more intelligently and ensure better performance across production stages.

Designed to Scale Across Industries

One of the key takeaways from OEM Day 2025 was the versatility of Delta’s automation platform. Whether supporting semiconductor manufacturing, electronics assembly, or precision inspection systems, OEMs can leverage a unified set of tools and technologies, offering streamlined development, reducing integration effort, and simplifying long-term maintenance. This flexible, scalable approach allows customers to build confidently for today, while staying ready to adapt as production demands evolve.

Interactive live demonstrations showcased real-world applications and system performance, giving attendees a hands-on look at how Delta’s solutions can be implemented to solve actual production challenges.

From single components to total solutions, Delta offers seamless hardware-software integration and implementation. As manufacturers embrace smarter, more connected production environments, Delta stands as a trusted partner, empowering OEMs with the tools, technologies, and collaboration they need to lead the next wave of industrial innovation.